Getting Started with 3D Printing: Tools, Materials, and Setup

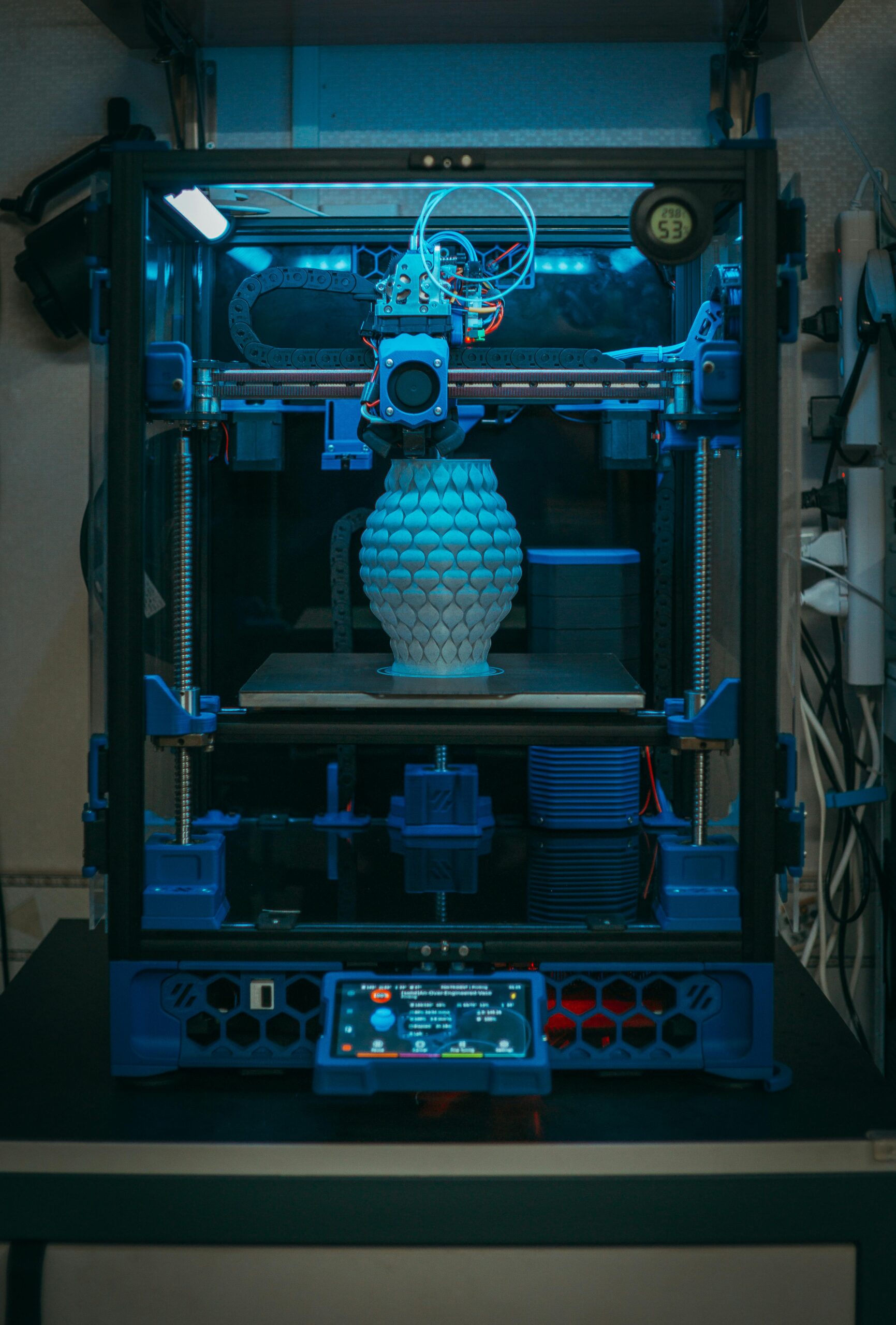

Embarking on a 3D printing journey from the comfort of your home can be both exciting and daunting. To build a successful side hustle, you’ll first need to amass the right tools and materials, beginning with the selection of an appropriate 3D printer. Depending on your budget and the quality of output you’re aiming for, you can choose between various types of printers: FDM, SLA, and SLS.

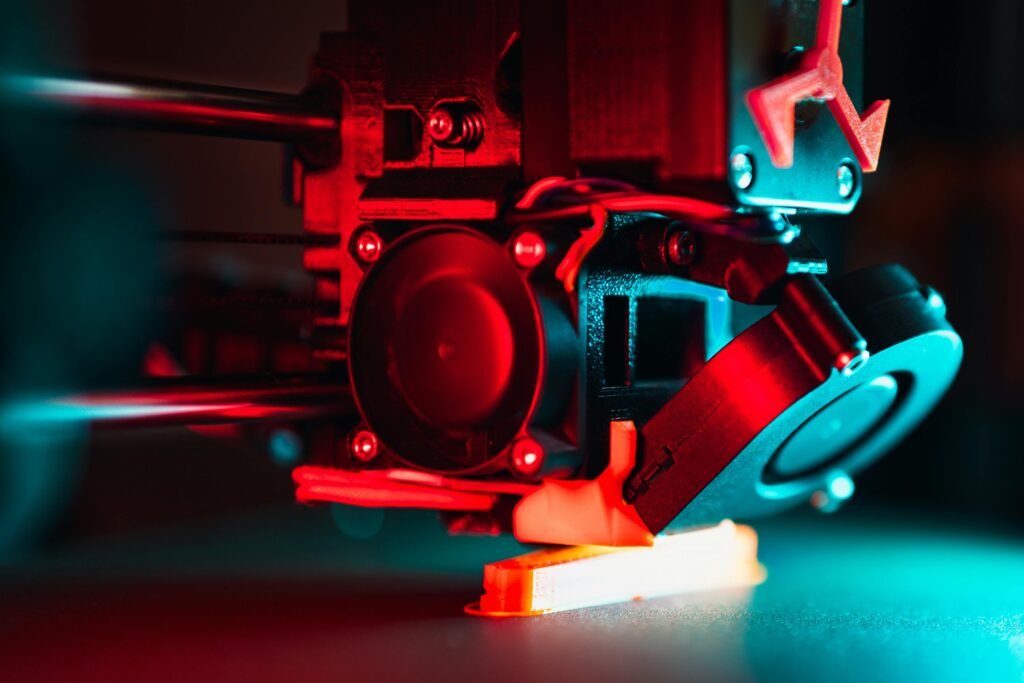

Fused Deposition Modeling (FDM) is the most accessible and economical option, well-suited for beginners aiming to produce functional prototypes and simple decorative pieces. Stereolithography (SLA) uses photopolymer resins and is ideal for achieving high resolution and detailed prints, though it comes at a higher cost. Selective Laser Sintering (SLS), a more advanced technology, is well-known for its ability to create durable and complex structures without the need for support structures, making it an attractive option for producing commercial-grade items.

Once you’ve selected your 3D printer, it’s paramount to source quality materials. For FDM printers, filaments such as PLA and ABS are prevalent, while SLA printers require specific resin types. It’s advisable to purchase materials from trusted suppliers to ensure consistency and reliability in your prints. Leading suppliers include MatterHackers, Filaments.ca, and Anycubic for filaments, while Formlabs and Photocentric offer high-quality resins.

Setting up a dedicated workspace is crucial for a safe and efficient operation. Choose a space that is well-ventilated to disperse any fumes or particulates generated by the printing process. A clutter-free, organized area with ample lighting will improve your workflow and reduce the risk of accidents. Investing in safety equipment, such as gloves and goggles, is recommended, especially when handling resins or solvents.

Finally, you will need the appropriate software to manage your designs and the printing process. A blend of computer-aided design (CAD) software and slicing software is necessary. Free CAD options include Tinkercad and FreeCAD, while more advanced users may prefer paid options like Fusion 360 or SolidWorks. For slicing software, Cura and PrusaSlicer are robust, no-cost solutions that convert CAD models into printable files, while Simplify3D is a reputable paid option offering advanced features for experienced users.

Turning Designs into Profit: Marketing, Customer Engagement, and Growth Strategies

Transforming a 3D printing hobby into a successful side hustle involves identifying and tapping into lucrative market opportunities. Enthusiasts can explore various niches, including custom jewelry, unique home decor items, prototypes for inventors, or cosplay accessories which have significantly gained popularity. Each niche offers distinct opportunities for creativity and profit, catering to different customer bases with specific needs and interests.

Effective marketing is essential to turn designs into profit. Start by establishing an online presence through well-known platforms such as Etsy, Amazon, or creating a dedicated website. These platforms simplify setting up a store, enable wider audience reach, and provide integral tools to manage sales and customer interactions. Quality product images, detailed descriptions, and clear policies will drive initial interest and trust.

Leveraging social media marketing can significantly enhance visibility and customer engagement. Platforms like Instagram, Facebook, and Pinterest are valuable for showcasing innovative designs and reaching potential customers. High-quality, engaging content, including images, videos, and customer testimonials, can attract and retain followers. Interacting with audiences through comments, messages, and posts helps build community and loyalty around products.

Customer engagement is pivotal for continuous improvement and retention. Actively seeking feedback through surveys, reviews, and direct communication can provide invaluable insights into product enhancements and new ideas. Responding to feedback with tangible improvements strengthens customer relationships and drives repeat purchases.

Pricing strategy also plays a crucial role in building a profitable 3D printing business. It’s imperative to balance competitiveness with profitability. Consider factors such as material costs, production time, market trends, and comparable prices. Experimenting with different pricing models, such as bundling products or offering limited-time discounts, can also attract diverse customer segments.

Scaling the business over time requires strategic planning and investment. Investing in higher-end equipment can improve production quality and expand capabilities. Streamlining production processes reduces time and costs, enhancing overall efficiency. Exploring partnerships, whether with other creators or businesses, can open new revenue streams. Additionally, crowdfunding can provide capital for larger projects, allowing for further expansion and exploration of innovative ideas.